What Is Built-Up Roofing?

There are so many options for flat roofs—it’s hard to choose. Investing in a roofing system is not cheap, and making a sound decision requires in-depth knowledge of each of your options.

If you own a commercial building, built-up roofing (BUR) is one of the cheapest and most reliable options available. We’ll talk about everything you need to know about BURs right here.

The Basics of Built-Up Roofing

Built-up roofing is a type of roofing that is most typically seen in commercial roofing. It’s almost exclusively used for flat to low-slope roofs. The systems are made by alternating layers of ply sheets and asphalt.

The multiple layers of roofing felt are typically applied with tar or hot asphalt which reinforces the fabric to create a tough roofing material.

Why Is It Used?

Shingles and tiles are good for sloped roofs. They guide the water away from the house. Flat and low-sloped roofs, however, aren’t able to divert water as effectively as a sloped roof.

BUR systems include a high waterproofing rating and are perfect for areas water tends to sit.

Installing Built-Up Roofing

The first step in installing a BUR roof system is laying down insulation. This goes directly onto the deck surface and is covered by asphalt and a cover board. This acts as the base sheet of the roofing system.

After that, ply sheets are installed one after the other with asphalt being applied in between each one. The ply sheets are usually made with felt or fiberglass. Layering these up like this is what creates such strong waterproofing. Even if the top layer is exposed, the other layers are still there.

The final sheet is topped with either a reflective roof coating, a cap sheet, or surfacing materials like gravel and stone.

Hot, Cold, and Ballasted Systems

The installation process can be applied in a couple of different ways—hot, cold, and ballasted.

Hot means the asphalt is hot-mopped over each sheet. Heat-applied systems are normal, but cold-applied systems are also available. Both of them work similarly, but the application process used different adhesive applications.

Ballasted systems are a lot different than the other two options. Ballasted built-up roof systems don’t use adhesives. Instead, the roof is set in place using the weight of the roof and the surface materials. Fasteners are used to minimize excessive movement, but other than that, it’s reliant on the weight to stay down.

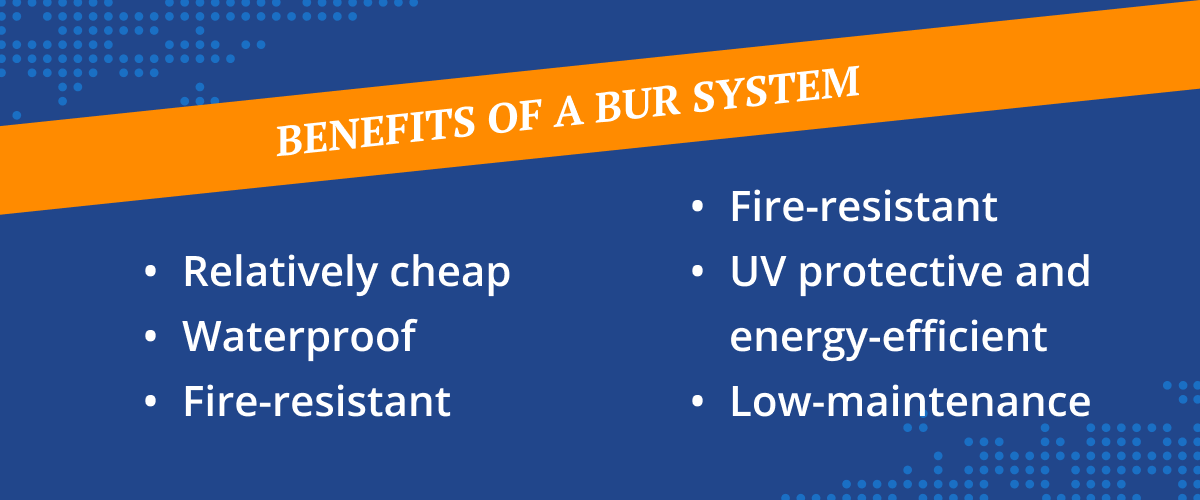

Benefits of a BUR System

Apart from being relatively cheap, BUR systems have several benefits.

Waterproof

Built-up roofs are a great option for flat roofs due to their waterproof capabilities. Because of the layers of tightened bitumen, these systems are great at stopping water.

Weatherproof

Built-up roofing systems are also resilient against harsh weather conditions. Having the addition of fiberglass and aggregate built into the system creates a strong shell that won't easily let up to intense weather.

Fire-Resistant

This may come as a shock, but BURs are fire-resistant. It takes a lot of heat to cause the tar to catch fire.

UV Protective and Energy-Efficient

The surface materials used in a built-up roof are made to reflect heat and UV rays. This will keep your building cool and decrease energy costs from running the A/C.

Low-Maintenance

Built-up roofs don’t require a lot of maintenance. It’s still advised to check your roof after major weather events and to get a professional inspection every year.

Maintaining a BUR System

Even though built-up roofs are low-maintenance, it’s still important to get periodic inspections. Roof inspectors will look for any crack in the system and pinpoint any issues that need to be repaired. If there is an issue, a section of your roof may need to be re-sealed and coated. This can happen in smaller areas of the roof and does not require a new system.

Every five years or so the surfacing material will also need to be redone. This is typically a smaller project but will improve the lifespan and efficiency of your roof.

Related: Here’s Why You Need a Roof Inspection

Legacy Repair Will Inspect and Coat BURs

Replacing your roof coating will significantly delay the need to replace your roof. If you want to extend the lifespan of your flat roof, it’s an important part of your maintenance plan.

For customers located in Phoenix, Arizona and surrounding areas, we offer inspection and coat replacements for BURs. Choose a certified repair company with long-term experience in Arizona for your roofing needs. We’ll help you become more informed about what your roof needs so you can be certain the job is done right.